In the broader term, heat exchangers are classified into four different metrics.

- The nature of the Heat Exchange Process

- The physical state of the fluids

- The heat exchanger’s flow arrangement

- The design and construction of the heat exchangers

1. Nature of the Heat Exchange Process

First and one of the most common classifications used to differentiate heat exchangers. As we know, two-fluid at different temperatures contact each other and exchange their heat in an exchanger. There is only two possible way of contact.

- Direct contact

- Indirect contact.

a. Direct Contact

In this type, the hot and cold fluids contact directly with each other. There is no surface available between the two fluids. This type of contact is an extremely effective means to transfer heat between two fluids. Direct contact heat exchangers may be a good choice if the hot and cold fluids are merely different temperature variations of the same fluid, or if the fluid mixture is a desired or irrelevant part of the industrial process.

You may found useful: Packed bed column and its types

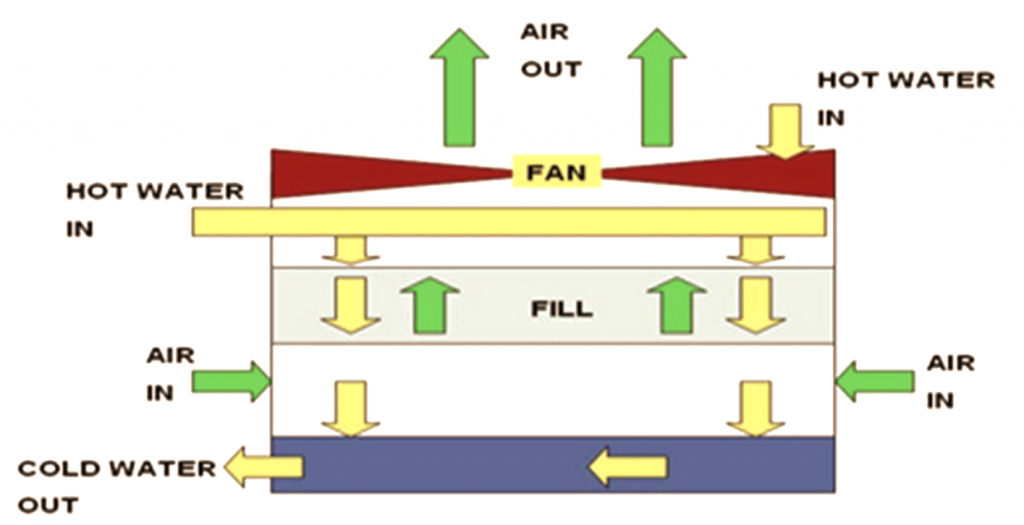

Cooling towers are the most common example of direct contact. In a cooling tower, the hot water from the heat exchanger network is showered at the top of the solid fill while air enters from the bottom and passes through the fill. Two fluids exchange their sensible heat while some amount of water also evaporates which causes the cooling effect that further reduces the temperature of the water. Air leaves the tower at the top while water is recycled from the bottom.

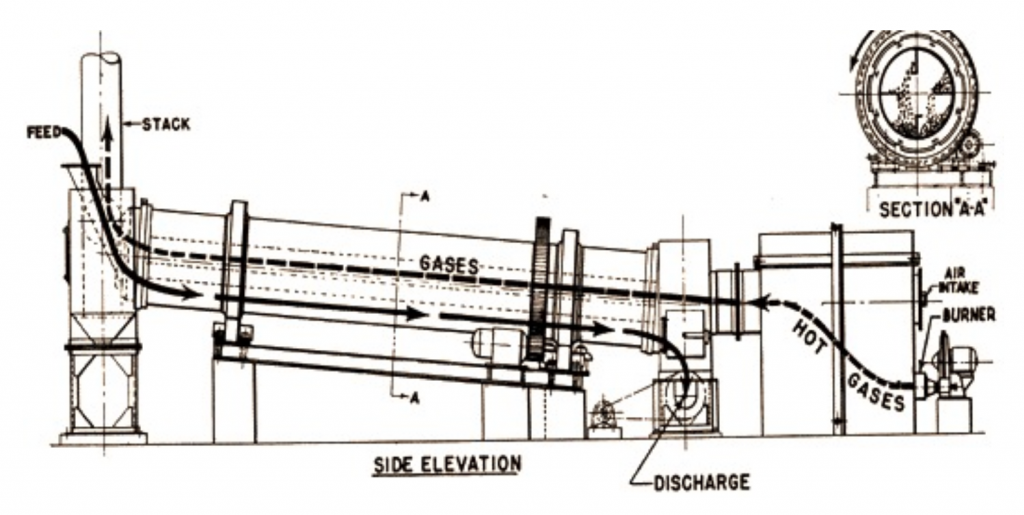

Another example of a direct contact exchanger is industrial dryers. In a typical dryer, the hot gases from the burner enter the dryers at the bottom while the feed, normally wet solid, enters from the top. The feed temperature increases by direct contact with the hot gases.

Other examples of direct contact are the scrubbers, steam stripping, and prilling tower.

b. Indirect contact

This type of contact in heat exchangers keeps the hot and cold fluids physically separated from each other. Typically, indirect contact heat exchangers will keep the hot and cold fluids in different sets of pipes. This is commonly done to prevent contamination of one fluid by the other.

One of the most common indirect contact type exchangers is a shell and tube heat exchanger. One fluid flows through the tube while the other flows through the space between the tubes and the outer shell. This space is referred to as an annulus. The heat between the fluid is exchanged through the tube’s wall. Although, these exchangers are less heat transfer than direct contact but are more common in the industry.

2. The Physical State of the Fluids

Heat exchangers may also be classified based on the physical state of the hot and cold fluids within the exchangers. For example:

- Liquid-Gas exchanger.

- Liquid-Solid Exchanger

- Gas solid exchanger

- Liquid-Liquid exchanger. This can be direct as well when liquids are immiscible.

3. Heat Exchanger’s Flow Arrangement.

This is one of the important classifications of heat exchangers. There are three types of flow arrangements possible within an exchanger.

- Parallel or co-current flow

- Countercurrent flow

- Crossflow.

a. Parallel Flow

In this heat exchanger, the hot and cold fluids enter the heat exchanger from the same end and flow parallel to each other. The benefits and drawbacks of this arrangement can be understood by its temperature profile. As the temperature difference is the driving force in the exchanger. The heat transfer is maximum when the fluids enter the exchanger.

Delta one shows the driving force at the inlet of the exchanger. The driving force gradually decreases as the fluid moves toward the exit. The minimum driving force can be observed near the exit of the exchanger. In this type, the minimum temperature of the hot fluid remains greater than the maximum temperature of the cold fluid. These types of heat exchangers are used when a sudden temperature change is required.

b. Countercurrent Flow

In this heat exchanger, the hot and cold fluids enter the heat exchanger from the opposite end and flow in opposite directions to each other. Again, the benefits and drawbacks of this arrangement can be understood by its temperature profile.

The driving force between two fluids can remain almost the same throughout the exchanger length but it mainly depends upon the temperature ranges of both fluids mean how much a fluid changes its temperature between the inlet and outlet of the exchanger. In this type, the minimum temperature of the hot fluid can be less than the maximum temperature of the cold fluid. These types of heat exchangers are used when a high heat transfer rate is required.

c. Cross-Flow

In cross-flow heat exchangers, the hot and cold fluids enter the heat exchanger at different points as they travel through the heat exchanger. they cross paths with each other, often at right angles. They are commonly used in gas heating applications. They have a large surface area which is good for transferring heat to gases.

4. Design and Construction of the Heat Exchangers

The last classification is the design and construction of heat exchangers. It is simple, each heat exchanger is different in design and construction. So, each exchanger is one type of this classification. For example:

- Double Pipe Heat Exchanger

- Shell and Tube Heat Exchanger

- Plate and Frame Heat Exchanger

- Air Cooler

- Cooling Tower

5 Comments

Aspen HYSYS simulation and design models of heat exchangers · November 29, 2022 at 10:10 pm

[…] Read also: Classification of Heat Exchangers […]

Conduction and its Mathematical Representation - Chemiopedia · December 1, 2022 at 7:20 pm

[…] Read also: Classification of Heat Exchangers […]

Cooling Towers and its Classification - Chemiopedia · December 1, 2022 at 7:27 pm

[…] Read More: Classification of Heat Exchangers […]

Double Pipe Heat Exchanger and its pros and cons · December 6, 2022 at 10:02 pm

[…] Read also: Classification of Heat Exchangers […]

TEMA Standard for Shell and Tube Heat Exchanger Design · December 12, 2022 at 6:38 pm

[…] Read also: Classification of heat exchangers […]

Comments are closed.