The Claus process is a process to separate elemental sulfur from the sub-stoichiometric combustion of hydrogen sulfide (H2S).

Overall reaction

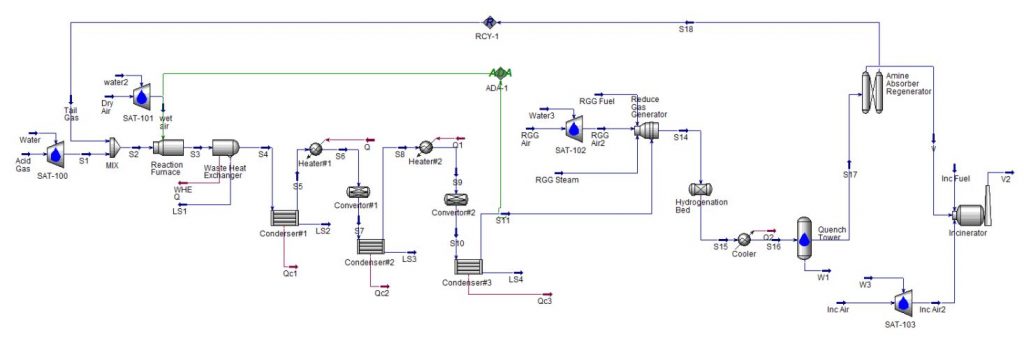

Figure 1 shows a typical process of a two-stage Claus process with Tail Gas Treating. Acid gas from the acid removal process and a small amount of recycling from the tail gas treating unit is fed to the reaction furnace. The feed is burned in the reaction furnace adiabatically and the outlet temperature of the reaction furnace is around 1100C.

The air in the furnace is sufficient enough to produce the overall mixture with the 2:1 stoichiometric ratio of hydrogen sulfide and sulfur dioxide. 2/3 of the total sulfur is formed in the furnace by the above reactions.

Read also: Amine Sweetening Process

The furnace product is cool down in the waste heat exchanger and the sulfur is a condenser in the condenser at 135C. Liquid sulfur is removed and the remaining stream is heated again to 270C and enters the first catalytic converter. Removal of the liquid sulfur from the stream provides the necessary driving force for further conversion in the catalytic convertor.

The above reactions occur in the convertor and more sulfur is produced. The product of the catalytic converter is condensed and liquid sulfur is removed. The remaining stream again heated to 210C and enter to the second catalytic converter. The sulfur is removed from the condenser and the remaining gases move to the tail gas treating unit. After two steps conversion, 98% of the total sulfur recovered from the acid gas stream. Sulfur products from the condensers are stored in the underground sulfur pit to be pumped for shipment.

Tail Gas Treating

The gas product from condenser # 3 moves to the in-line burner to pre-heat the stream before entering the hydrogenation reactor. In the hydrogenation reactor, the elemental sulfur converts to hydrogen sulfide. The effluent from the hydrogenation reactor is cooled down to 150C by producing low-pressure steam. The stream is further cool down in a quenching tower using the water as a quenching medium. The outlet temperature of the tower is as low as 35C.

The residual hydrogen sulfide is removed with the amine unit. The treated tail gas was removed from the absorber and passed through to the incinerator for the destruction of the remaining hydrogen sulfide. The acid gases from the stripper are recycled back to the upstream of the reaction furnace.