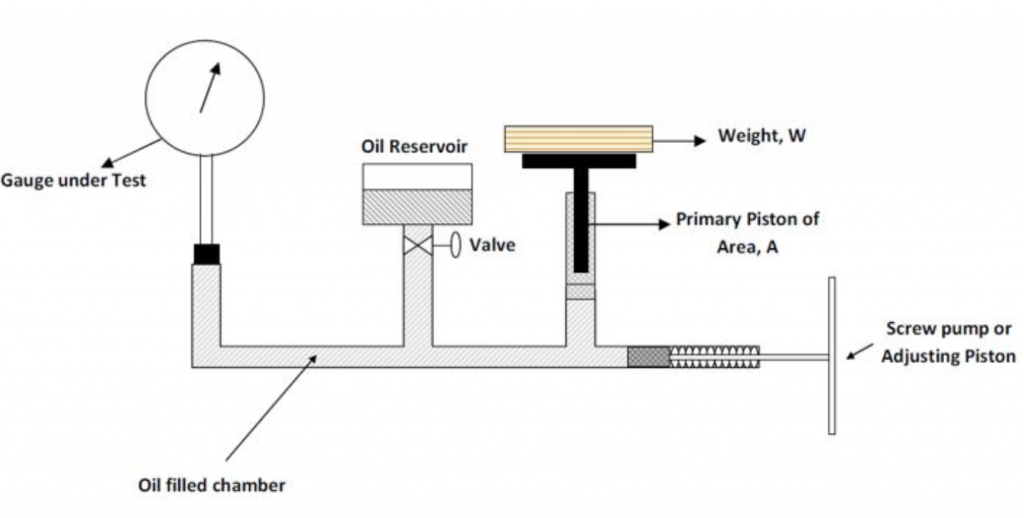

Deadweight Testers for Pressure Testing

Deadweight testers (DWT) are used to determine the operating pressure in a closed and compressed fluid system. They are named so because they use dead weights to balance the system pressure. Each applied weight is stamped with the equivalent amount of force that will be exerted on a predetermined area of piston-cylinder arrangement by using that weight.

Working Principle

DWT is based on the principle of Pascal’s law. The law states that in a closed system of an incompressible fluid, the pressure applied will exert an equal amount of force in all directions. In the DWT system, silicon oil is used within the closed boundaries of the Piston cylinder arrangement, piping, pressurization chamber, and in the head on which the pressure is applied. The oil is taken into the pressurization chamber from the oil bowl and all the air entrapped is vented off. This is because of the reason that air is compressible and hence does not allow pressure to be exerted equally in all the areas and thereby creating an error in the test results.

Read also: Level measuring devices

Once the system is full of air-free oil, the pressure is gradually increased from the pressurization chamber. Oil pressure starts increasing in all the areas including the piston-cylinder arrangement over which the dead weights are mounted. As the force increases gradually and equals the amount of downward force being exerted by the dead weights, the total system gains the state of equilibrium, and just at that moment, the dead weights start getting lifted up. At this condition, the amount of force operating in the entire system is the same. The sum of pressure values stamped on weights lifted is operating on the pressure gauge element also, which is under test.