Flow measuring devices are important in the industry to maintain the reactant and product flow rates to meet the desired quality. The article enlists the major flow-measuring devices found in the industry.

1. Orifice plate

1.1. Construction

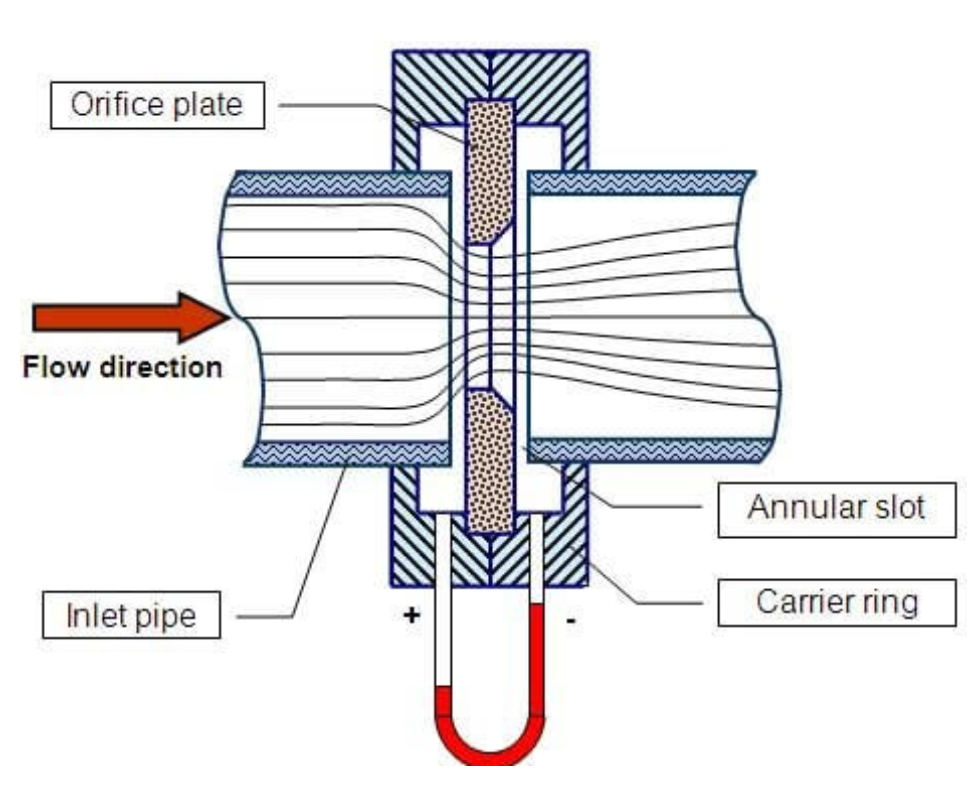

An Orifice Meter is basically a type of flow meter used to measure the rate of flow of Liquid or Gas, using the Differential Pressure Measurement principle. It is mainly used for robust applications as it is known for its durability and is very economical.

Read also: Flow Measuring Devices in Industry

As the name implies, it consists of an Orifice Plate which is the basic element of the instrument. When this Orifice Plate is placed in a line, a differential pressure is developed across the Orifice Plate. This pressure drop is linear and is in direct proportion to the flow rate of the liquid or gas. Since there is a drop-in pressure, just like the Turbine Flowmeter, hence it is used where a drop-in pressure or head loss is permissible.

1.2. Types of Orifice

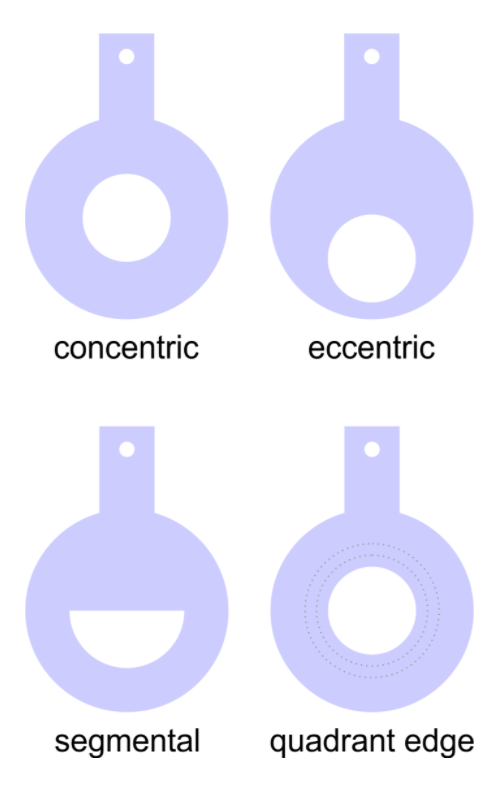

Orifice meters are built in different forms depending upon the application-specific requirement, The shape, size, and location of holes on the Orifice Plate describe the Orifice Meter Specifications as per the following:

- Concentric Orifice Plate

- Eccentric Orifice Plate

- Segment Orifice Plate

- Quadrant Edge Orifice Plate

1.2.1. Concentric Orifice Plate

It is made up of SS and its thickness varies from 3.175 to 12.70 mm. The plate thickness at the orifice edge should not be exceeded by any of the following parameters:

- D/50 where D = The pipe inside diameter

- d/8 where d = orifice bore diameter

- (D-d)/8

*Beta Ratio(β): It is the ratio of the orifice bore diameter (d) to the pipe inside diameter (D).

1.2.2. Eccentric Orifice Plate

It is similar to the Concentric Orifice plate other than the offset hole which is bored tangential to a circle, concentric with the pipe, and of a diameter equal to 98% of that of the pipe. It is generally employed for measuring fluids containing:

- Media having Solid particles.

- Oils containing water.

- Wet steam.

1.2.3. Segment Orifice Plate

It has a hole which is a semi-circle or a segment of a circle. The diameter is customarily 98% of the diameter of the pipe. They’re suitable for a fluid having solid particles in them.

1.2.4. Quadrant Edge Orifice Plate

This type of orifice plate is used for flow such as crude oil, high-viscosity syrups or slurries, etc. It is conceivably used when the line Reynolds Numbers range from 100,000 or above or between 3,000 to 5,000 with an accuracy coefficient of roughly 0.5%.

1.3. Advantages of Orifice meter

- The Orifice meter is very cheap as compared to other types of flow meters.

- Less space is required to Install and hence ideal for space-constrained applications

- The operational response can be designed with perfection.

- Installation direction possibilities: Vertical / Horizontal / Inclined.

Read also: Level Measuring Devices in the Industry

1.4. Limitations of Orifice meter

- Easily gets clogged due to impurities in gas or in unclear liquids

- The minimum pressure that can be achieved for reading the flow is sometimes difficult to achieve due to limitations in the vena-contracta length for an Orifice Plate.

- Unlike the Venturi meter, downstream pressure cannot be recovered in Orifice Meters. Overall head loss is around 40% to 90% of the differential pressure.

- Flow straighteners are required at the inlet and the outlet to attain streamlined flow thereby increasing the cost and space for installation.

- Orifice Plate can get easily corroded with time thereby entails an error.

2. Venturi Meter

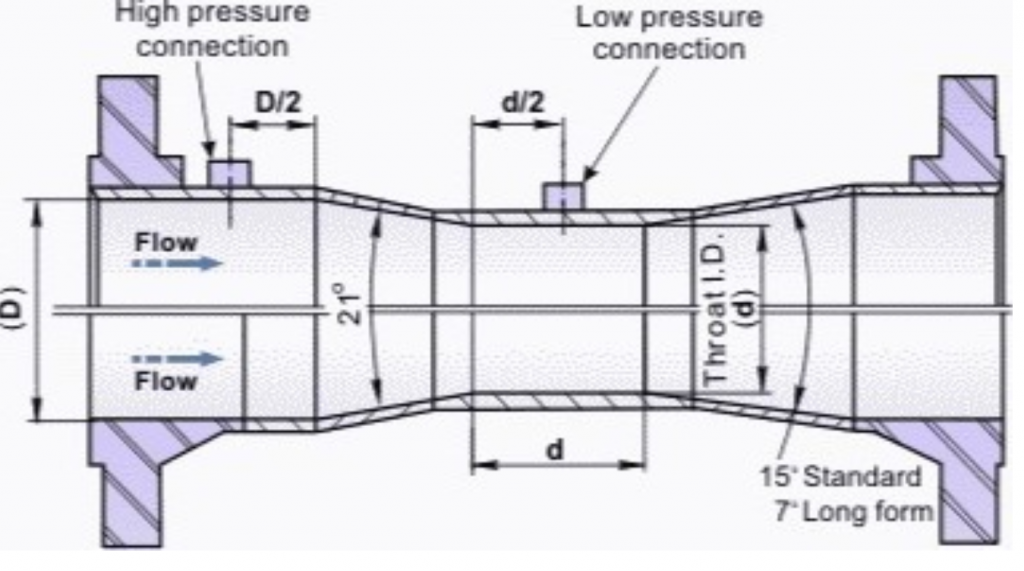

Venturi meters are flow measurement instruments that use a converging section of pipe to give an increase in the flow velocity and a corresponding pressure drop from which the flow rate can be deduced. They have been in common use for many years, especially in the water supply industry.

Various forms of construction of a Venturi meter are employed, depending on size, but all are considerably more expensive than the orifice plate. However, because most of the differential pressure is recovered by means of the divergent outlet section, the Venturi causes less overall pressure loss in a system and thus saves energy: the overall pressure loss is generally between 5 and 20 percent of the measured differential pressure. The Venturi meter has an advantage over the orifice plate in that it does not have a sharp edge that can become rounded; however, the Venturi meter is more susceptible to errors due to burrs or deposits around the downstream (throat) tapping.

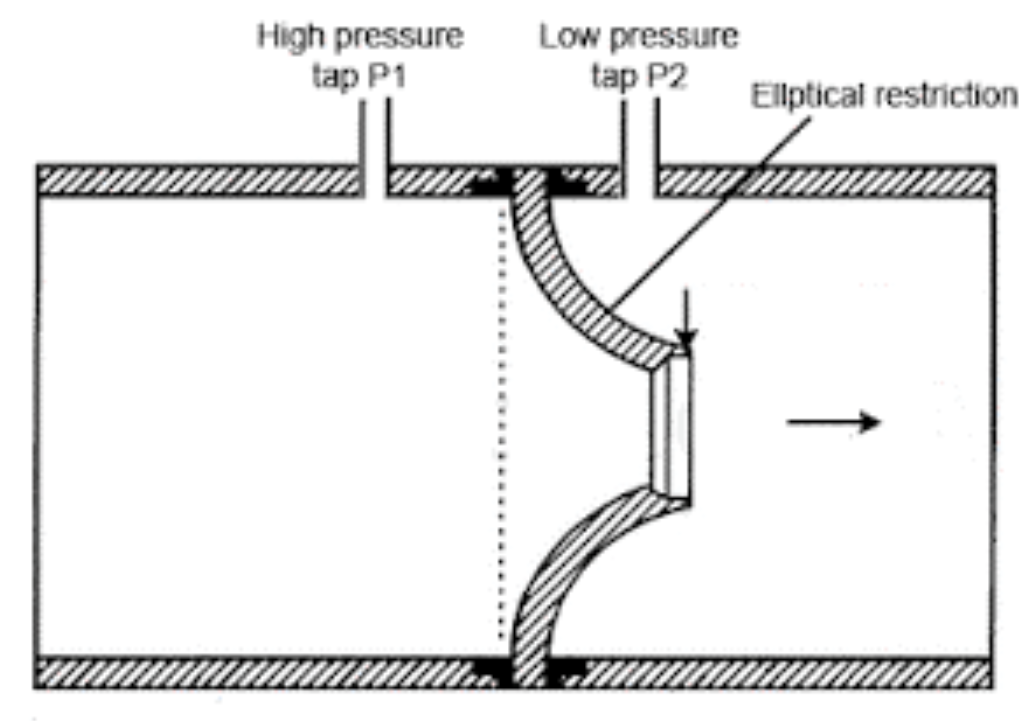

3. Flow nozzle

Flow nozzle is similar to a venturi meter, its shape provides lesser resistance to flow, and it has a higher coefficient of discharge. Moreover, it has no divergent cone for pressure recovery.

The nozzle meter is bolted between flanges of pipes carrying fluid. The pressure upstream and downstream is measured using a differential pressure sensor.

3.1. Advantages

- Compact and low dimensional as compared to the venturi meter.

- Cheaper and easy to install.

- High coefficient of discharge.

- Less susceptible to wear.

3.2. Disadvantages

- Low-pressure recovery

- It cannot be used for low-pressure head

- Cannot be used for a fluid having the solid particles

4. Turbine flow meter

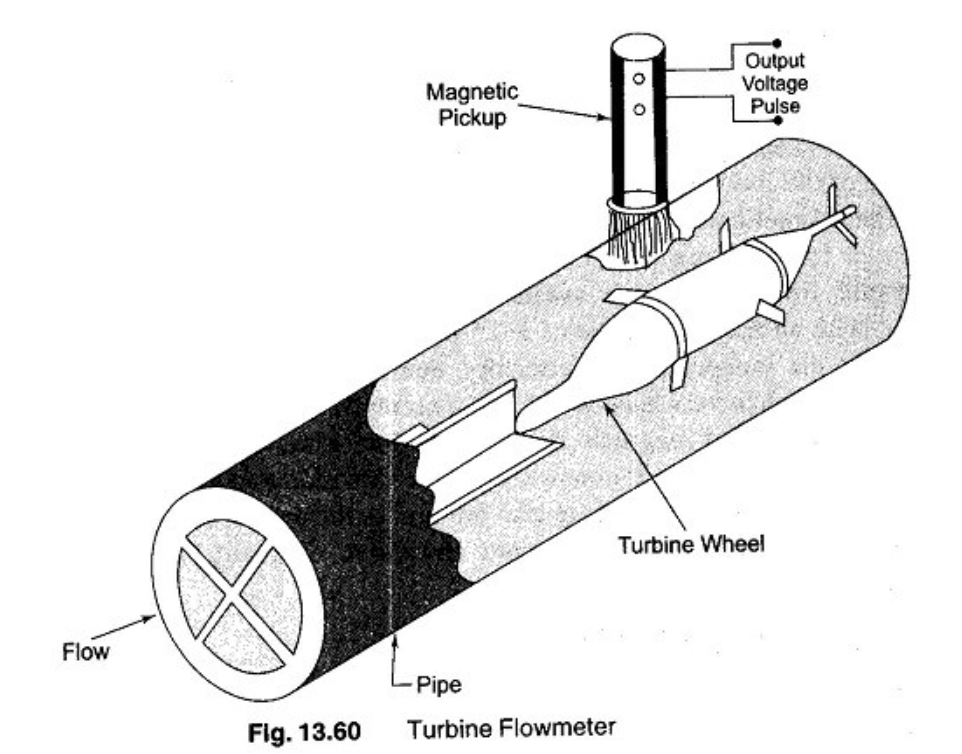

The Turbine Flowmeter Principle is used for the measurement of liquid gas and gases of a very low flow rate. It works on the principle of the turbine. It consists of a multibladed rotor (called turbine wheel) which is mounted 90° to the axis of the flowing liquid as shown in Fig

The rotor is supported by the ball or sleeve bearings on a shaft which is retained in the flow meter housing by a shaft support section. The rotor is free to rotate about its axis.

The flowing liquid strikes the turbine blades (rotor) imparting a force to the blade surface which causes the rotation of the rotor. At a steady rotational speed, the speed of the rotor is proportional to the fluid velocity and hence to the volumetric flow rate. The speed of rotation is monitored by a magnetic pick up which is fitted to the outside of the meter housing.

4.1. Advantages

- The plot of the volumetric flow is continuous since the turbine is constantly rotating with a speed. Of course, it would be zero if the flow stops as well. Repeatability is a highly desirable factor in any flow meter

- The rate of response for a turbine flow meter is quite fast (down to about a quarter of a second)

- Accuracy is very good (about ±0.25%)

- Rugged nature of the flow meter, allowing for daily usage

- Modifiable to take into consideration various extra features like temperature compensation, viscosity, and effects of density

4.2. Disadvantages

- Expensive to set up with all options

- The lower end can accumulate viscosity, resulting in loss of accuracy although that can be compensated for by the use of jeweled pivot and low drag fluid bearings

- The solids mixed in the fluid must be of a negligible size to allow for the turbine to work seamlessly over a large period of time

- Application of flow straighteners are highly desirable in case of uneven flow of fluid

- Of course, the efficiency of the whole setup is, in the end, dependent on the expertise of those operating.

1 Comment

Pump types, their specifications, and applications · December 9, 2022 at 11:04 am

[…] Read also: Flow measuring devices and their pros and cons […]

Comments are closed.