Level measurement is an important parameter in a processing facility. There are multiple types of level sensing elements. A few of them are listed below:

Gauge Glass

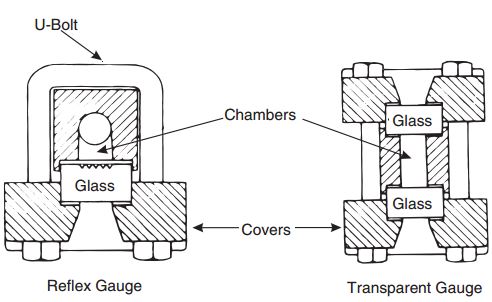

Gauge glass is the most common level sensor type used in the industries. There are two common classifications of gauge glass:

Transparent Type – in which the gauge glass consists of a glass tube or the flat glass plate arrangement. The process fluid can directly be viewed through the transparent type. They are used for opaque fluids.

Reflex Type – In this type, the reflecting prisms are used to aid the visibility of transparent fluids.

Caution should be made for the handling and installation of gauge glasses. Scratches or chips can reduce the strength of the glass and cause safety problems.

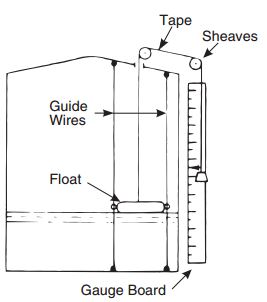

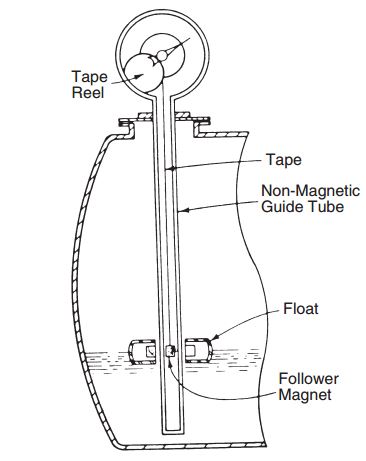

Chain and Tape Float Gauges

These types of gauges are used in the large atmospheric storage tanks where the entire full to the empty range must be measured periodically. These gauges are common in crude and condensate storage tanks.

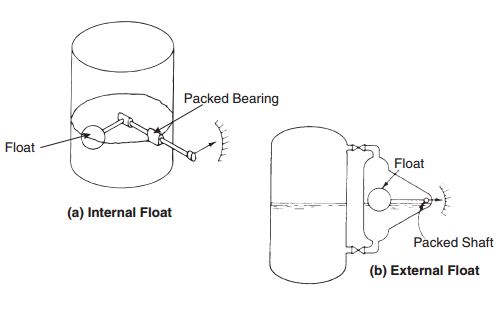

Lever and Shaft Float Gauges

These gauges can be used on both, pressurized and unpressurized tanks. The measurement of these gauges is limited to a small level. The range of measurement is determined by the length of the float arm but generally is between a few inches and a few feet.

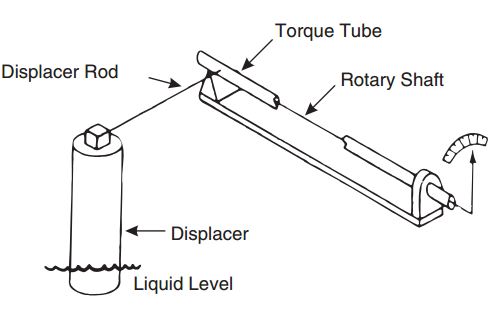

Displacer Level Measuring Device

This is one of the most common types of level measuring devices. This is also called torque tube displacer. It is attached to the free end of a torque tube which has elastic properties that permit it to twist as the displacer tries to float with change in level. The indicator or transmitter reads the slight turning of the free end of the torque tube.

They are generally not recommended for level measurement greater than 10 feet.

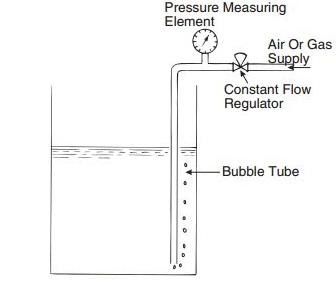

Head-Pressure Level Gauges

The liquid level in a vessel can be determined by the hydrostatic head of the liquid. The level is calculated by dividing the measured hydrostatic head by the density of the liquid. This method requires a knowledge of the densities of all phases of the liquid. This can be done by:

- Pressure gauges

- Bubble tubes

- Differential pressrue

The bubbler is used at vacuum and low pressures and is especially good for services such as molten sulfur and dirty liquids.

Read also: Flow measuring devices

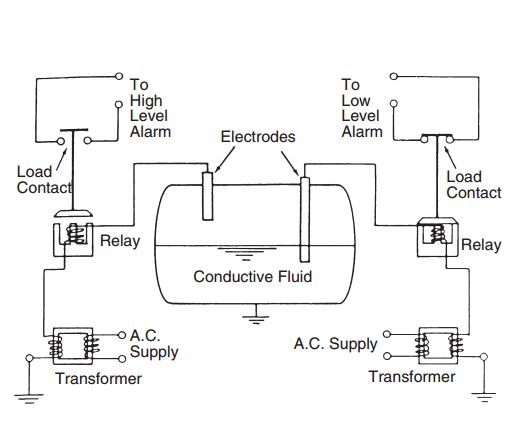

Electrical type level gauges and switches

There are two types of electric type level gauges

Float magnetic gauge – The follower magnet tracks the float at the liquid level. The magnet is connected to the tensed reel that indicates the level of the liquid on the gauge.

Conductive gauge – These gauges are generally used for high and low liquid level switches as shown in the figure.

4 Comments

Flow Measuring Devices in Industry - Chemiopedia · September 23, 2022 at 10:26 pm

[…] Read Also: Level measuring devices […]

Deadweight Testers for Pressure Testing - Chemiopedia · October 3, 2022 at 4:19 pm

[…] Read also: Level measuring devices […]

Pressure Sensing Devices in the Industry - · December 3, 2022 at 4:03 pm

[…] Read also: Level Measuring Devices in the Industry […]

Temperature sensing elements and their pros and cons · December 12, 2022 at 6:34 pm

[…] Read also: Level Measuring Devices in the Industry […]

Comments are closed.