Type of Phase Separators

- Horizontal two-phase separator

- Horizontal double-barrel two-phase separator

- Horizontal three-phase separator

- Vertical two-phase separator

- Vertical three-phase separator

1. Horizontal Two-Phase Separator

The fluid enters the separator and hits an inlet diverter cause a sudden change in the momentum. The initial separation occurs at the deflecting plate. The fall out of the gas stream to the bottom of the vessel is due to the force of gravity. This liquid collection separation provides the retention time required to let entrained gas evolve out of the oil and rise to the vapor space. The liquid then leaves the vessel through the level control valve. The gas flows over the inlet deflecting plate and then horizontally through the gravity settling section above the liquid. As the gas flows through this section, the small droplets of the liquid that were entrained in the gas and not separated by the inlet diverter are separated by gravity and fall to the gas/ liquid interface.

Some of the drops are of such small diameter that they are not easily separated in the gravity settling section. Before the gas leaves the vessel, it passes through a mist eliminator. This section uses elements of vanes, wire mesh, or plates to remove the very small of the liquid droplets of liquid before the gas leaves the vessel.

Read More: Two-Phase Separator Design

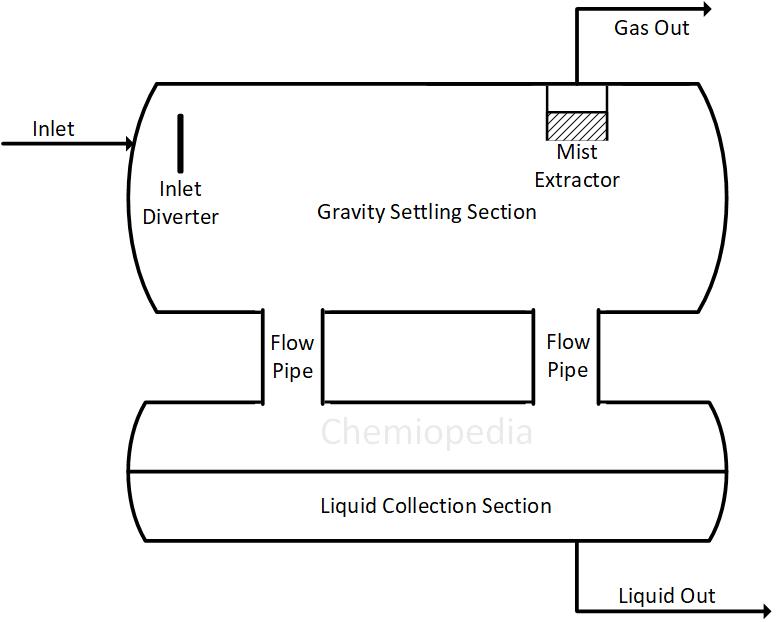

2. Horizontal double barrel two phase separator

Horizontal double-barrel two-phase separators are used where the gas-liquid ratio is high. In these designs, the gas and liquid chambers are separated. In the upper barrel, the inlet flow stream enters the vessel and strikes the inlet diverter. The free liquid falls to the lower barrel through flow pipes while the gas flows through the gravity settling section and leaves the separator through the mist eliminator.

The liquid drains through a small flow pipe into the lower barrel and flows up through the flow pipes. In this manner, the liquid accumulation is separated from the gas stream so that there is no chance of entrainment due to high gas velocity.

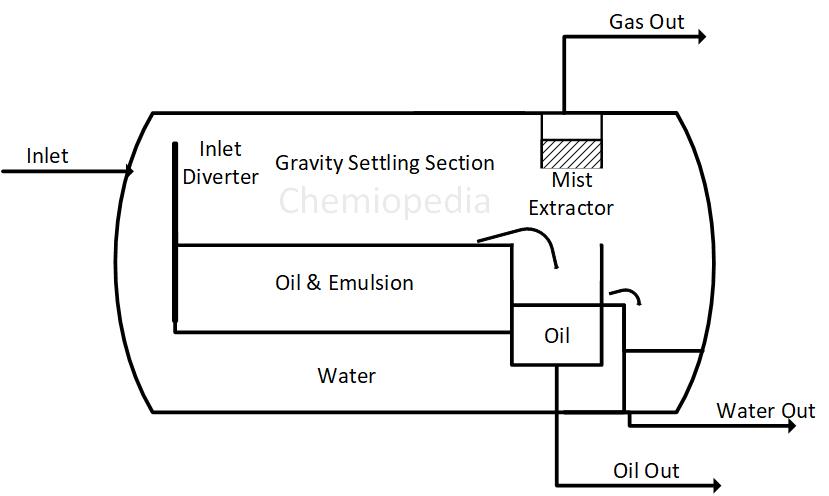

3. Horizontal three phase separator with Weir

The fluid enters the separator and hits an inlet diverter same as the other types of separators. However, in this type, the inlet diverter contains a downcomer that directs the liquid flow below the oil/water interface. This forces the inlet mixture of oil and water to mix with the continuous phase of water in the bottom and rise through the interface. It helps to coalesce the droplets of water that are entrained in the oil phase. The liquid collecting section of the vessel provides sufficient time so that the oil and emulsion form a layer at the top and free water settles to the bottom. The weir maintains the oil level and the level controller maintains the water level. The oil is skimmed over the weir. The produced water flows from a nozzle in the vessel located upstream of the oil weir. The gas flows horizontally and out through a mist extractor to downstream processing.

4. Horizontal three phase separator with Bucket

The horizontal three-phase separator with Bucket eliminates the need for a liquid interface controller. Oil skims and collects in the bucket where it is charged towards storage. The water flows under the oil bucket and then over a water weir to the water collection section. The height of the weir controls the liquid level in the vessel. The difference in height of the oil and water weirs controls the thickness of the oil layer due to specific gravity differences. This type is useful when oil flow is relatively small as compared to water.

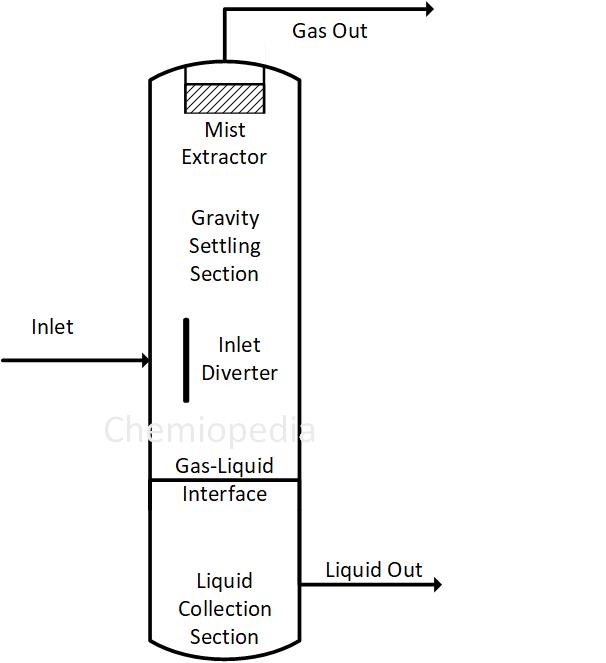

5. Vertical two-phase separator

In the verticle separator, the inlet flow enters the vessel through the side. As in the horizontal separator, the inlet diverter does the initial separation by sudden break-in momentum. The liquid flows down to the liquid collection section of the vessel. Liquid continues to flow downward through this section to the liquid outlet.

The gas flows over the inlet diverter and then vertically upward toward the gas outlet. In the gravity settling section, the liquid drops fall vertically downward counter to the gas flow. Gas goes through the mist extractor section before it leaves the vessel towards downstream processing.

Read More: Two-Phase Separator Design

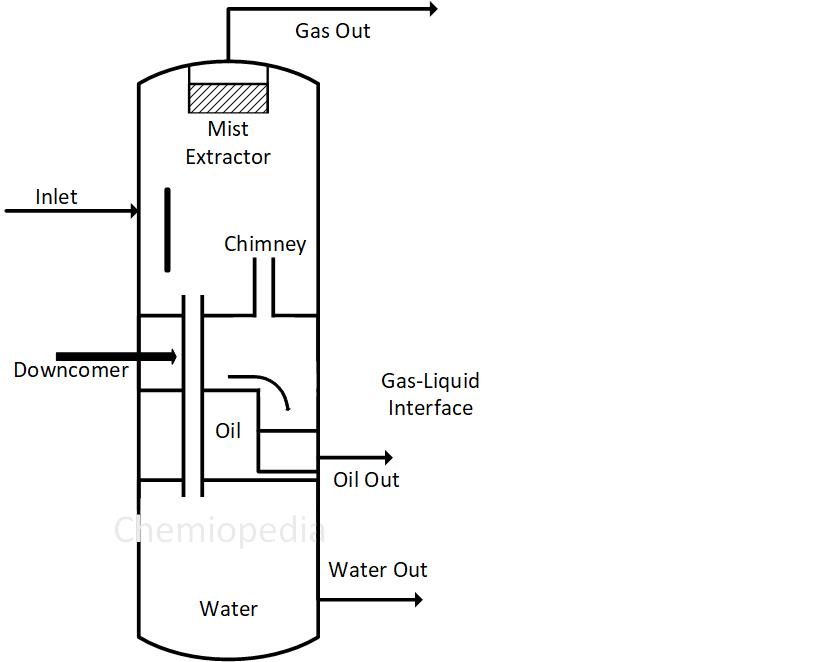

6. Vertical three phase separator

Flow enters the vessel through the side as in the horizontal separator, the inlet diverter separates the bulk of the gas. A downcomer is required to transmit the liquid through the oil-gas interface so as not to disturb the oil skimming. A chimney equalizes gas pressure between the liquid and gas sections.

The downcomer outlet is located at the oil-water interface. From this point, as the oil rises any free water trapped within the oil phase separates out. The water droplets flow countercurrent to the oil. Similarly, the water flows downward and oil droplets trapped in the water phase tend to rise in countercurrent to the water flow.

Read More: Three-Phase Separator Design