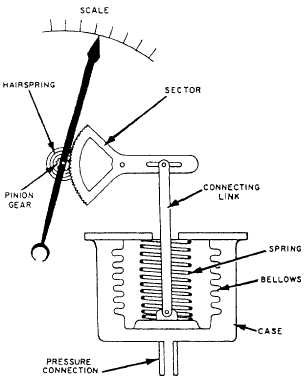

Bellow

These types of pressure gauges are sensitive to very low pressure and thus make it possible to specify low pressures with the help of a proper indicating mechanism. They are sensitive and strong enough to deliver accurate readings in any type of recording device. They are employed in conjunction with a spring to increase their range without damaging the elastic element.

In the simplest case, the pressure is applied to the internal side of the bellow, and through a proper mechanical linkage, it is communicated to a pointer indicating reading on a scale. A bellow’s elastic behavior resembles that of a helically coiled compression spring and is within the elastic limits of the bellow material. The relationship between the deformation and the force applied is a linear one.

Read also: Level Measuring Devices in the Industry

Most bellows assemblies are spring-loaded and the pressure indicator is the result of the force acting on the bellow and the opposing force of the spring. A bellow can be used to measure absolute pressure by liberating it from the effect of atmospheric pressure. This is done by using bellow in an enclosed vacuum case. The pressure is applied inside of the bellow and only this pressure is responsible for the reading on the pressure scale.

Bourdon Tube

For high-pressure measurements, Bourdon-type pressure gauges are more advantageous because of their high mechanical strength with a reduced area for pressure to work against and a high spring rate. Bourdon tubes are circular shaped tubes with an oval cross-section and are mainly found in the following three shapes:

- C-shaped

- Helical

- Spiral

Bourdon tubes have one end fixed and one free end. When pressure is applied within the tube the surface area of the tube tends to change. The distension caused in the tube ultimately straightens the tube slightly and gradually until the pressure is balanced by the elasticity of the element. The end that is fastened to a fixed position remains static, the free end thus moves when the pressure develops inside the tube and the movement of the free end can be transmitted through a pointer to indicate reading on a scale or it can be connected to any other electrical transducers or recording device through a mechanical linkage.

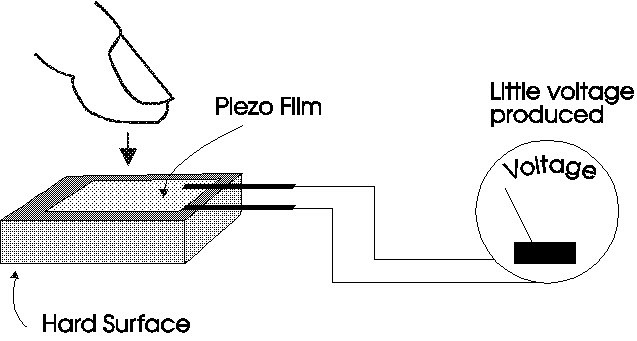

Piezoelectric element

Piezoelectric transducers have gained popularity as pressure transducers because of their ability to measure dynamic pressure. They are used to measure rapidly varying pressure. Their distinctive feature is the primary sensing element of a piezoelectric material such as crystals or quartz. When such a material is subjected to some force or pressure, voltage is generated which is proportional to the force applied. This property of piezoelectric materials was utilized for pressure measurement when the amplification of singles was made possible.

Read also: Flow Measuring Devices in Industry

Piezoelectric devices are classified into different types depending on the property of the piezoelectric element that is measured. It can be the material’s electrostatic charge, its resistivity, or its resonant frequency. Depending on which property is measured, the sensors are called electrostatic, piezoresistive, or resonant respectively.

1 Comment

Piping Hydro Test after a Construction/Maintenance Activity · December 3, 2022 at 4:24 pm

[…] Read also: Pressure Sensing Devices in the Industry […]

Comments are closed.