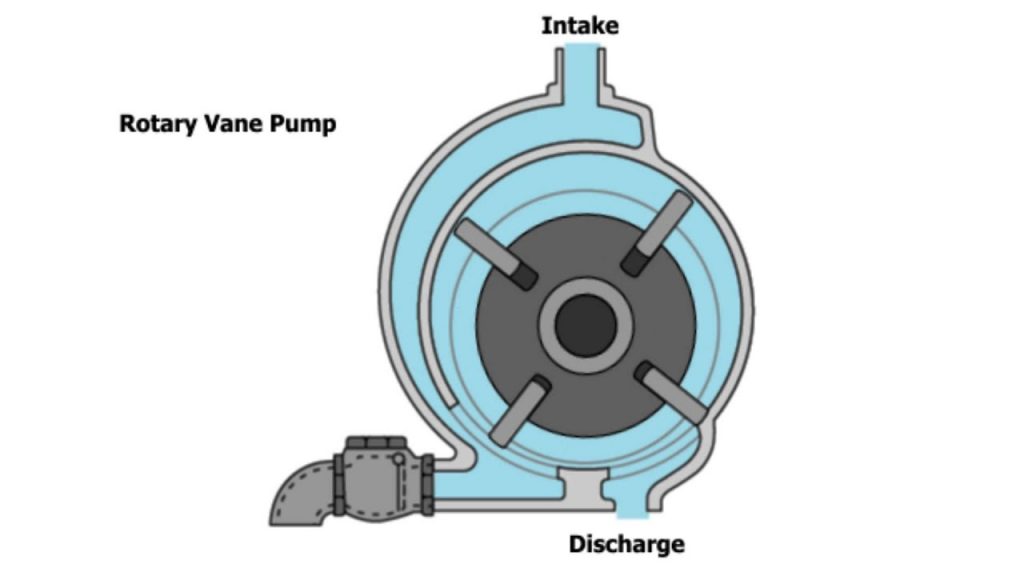

If a pump consists of vanes fixed to a rotor that rotates inside a cavity then it is known as Rotary Vane Pump. It is a positive displacement pump. In some cases, these vanes are variable in length and tensioned to maintain contact with the walls when the pump rotates.

Read also: Flow Measuring Devices in Industry

Design

A rotary vane vacuum pump is an oil-sealed rotary displacement pump. The pumping system consists of a housing:

- Vanes.

- An eccentrically installed rotor.

- That move radially under centrifugal and resilient forces and the inlet and outlet.

- The inlet valve, if available, is designed as a vacuum safety valve that is always open during operation.

- The working chamber is located inside the housing and is restricted by the stator, rotor, and vanes.

- The eccentrically installed rotor and vanes divide the working chamber into two separate compartments with variable volumes.

As the rotor turns, gas flows into the enlarging suction chamber until it is sealed off by the second vane. The enclosed gas is then compressed until the outlet valve opens against atmospheric pressure. The outlet valve is oil-sealed. When the valve is open, a small amount of oil enters the suction chamber and not only lubricates it but also seals the vanes against the housing (stator).

Working

The simplest vane pump is a circular rotor rotating inside of a larger circular cavity. The centers of these two circles are offset, causing eccentricity. Vanes are allowed to slide into and out of the rotor and seal on all edges, creating vane chambers that do the pumping work. On the intake side of the pump, the vane chambers are increasing in volume.

These increasing volume vane chambers are filled with fluid forced in by the inlet pressure. Inlet pressure is actually the pressure from the system being pumped, often just the atmosphere. On the discharge side of the pump, the vane chambers are decreasing in volume, forcing fluid out of the pump. The action of the vane drives out the same volume of fluid with each rotation. Multistage rotary vane vacuum pumps can attain pressures as low as 10−6 mbar (0.0001 Pa).

Application

- Common uses of vane pumps include high-pressure hydraulic pumps and automotive

- Pumps for mid-range pressures include applications such as carbonators for fountain soft drink dispensers and espresso coffee machines.

- Vane pumps can be used in low-pressure gas applications such as secondary air injection for auto exhaust emission control, or in low-pressure chemical vapor deposition systems

- Rotary vane pumps are also a common type of vacuum pump, with two-stage pumps able to reach pressures well below 10−6 bar.

2 Comments

Progressive Cavity Pump, its Working and Applications - · December 3, 2022 at 3:51 pm

[…] Read also: Rotary Vane Pump, its parts, working, and Applications […]

Peristaltic Pump; its working, and Applications · December 3, 2022 at 4:30 pm

[…] Read also: Rotary Vane Pump, its parts, working, and Applications […]

Comments are closed.