The amine sweetening process is the process used to remove acid gases like CO2 and H2S from natural gas. The process selected depends upon the different factors. Some of these factors are given below:

- H2S and mercaptan concentration in the sour gas

- Sales gas H2S and total sulfur limits

- Sales gas CO2 limit

- Gas flow rate

Read also: Nitrogen Rejection Process for Natural Gas

1.1. Process Description

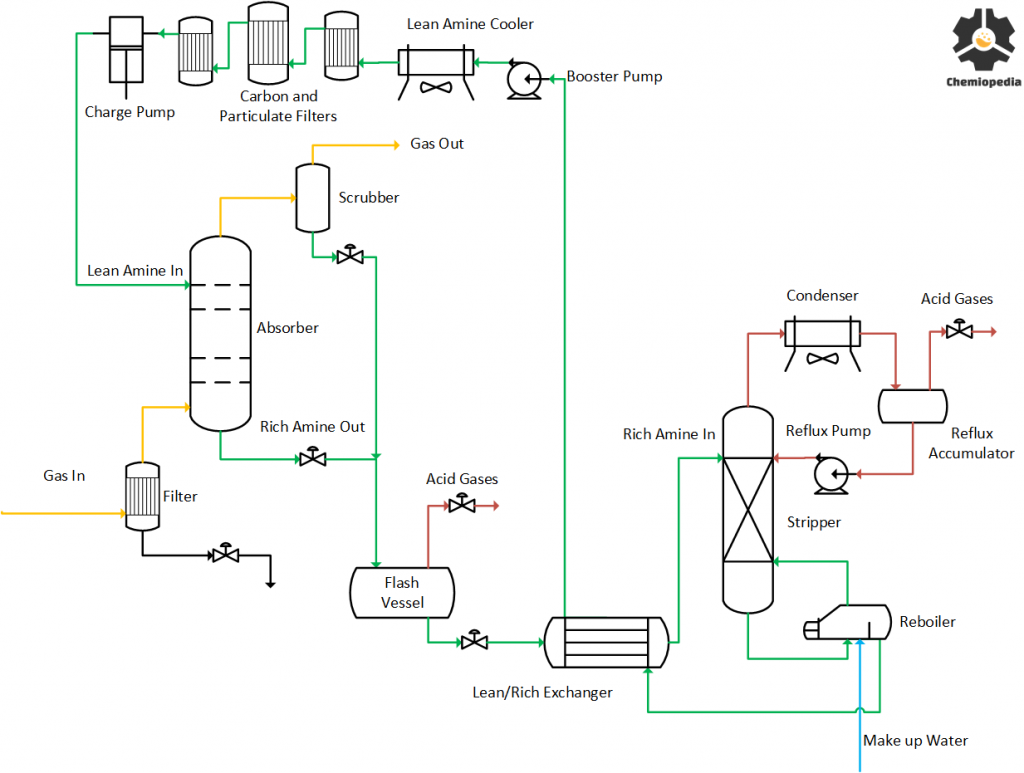

The Amine treating plant generally uses an amine solution for the removal of carbon dioxide and hydrogen sulfide (if present) from natural gas by chemical absorption. The sour feed gas is pre-treated to remove any entrained solids or liquids from the separator by passing through a Coalescing Filter Separator prior to entering the Amine Contactor Tower. The gas proceeds through the contactor column where the acid gases (H2S & CO2) are removed from the gas stream. The sweetened gas flows through the Gas Cooler where it is cooled before going to the Gas Scrubber. The Gas Scrubber removes any liquid that is condensed by the Gas Cooler before the sweet natural gas leaves the plant.

The lean amine is fed into the top of the Amine Contactor and flows countercurrent to the natural gas down through the trays where it contacts the natural gas and collects CO2 by absorption and chemical reaction. This rich amine collects at the bottom of the tower. The rich amine level in the contactor is maintained by a pneumatic level controller and control valve which dumps the rich amine into the Flash Separator. In the Flash Separator, any hydrocarbon gases entrained in the amine are flashed off along with the negligible amounts of acid gases and directed for disposal via a backpressure control valve.

From the Flash Separator, the rich amine stream is directed through the carbon filter for the absorption of hydrocarbons and degraded products from the amine. After Carbon Filter enters the amine sock filter where any remaining solid contaminants removal takes place. The rich amine continues to the Amine Exchanger where it is heated. The amine then enters the Amine Stripper Tower and flows down the still through the trays where contact with the steam coming from the reboiler, strips the acid gases from the amine. The amine is collected in a draw-off and is gravity fed to the bottom of the Direct Fired Reboiler.

In the Reboiler, the solution is heated until a portion of the water is vaporized. This liquid/vapor mixture is piped back to the Still column sump below the trays. As the steam travels up in the column through the trays it strips the acid gases from the rich amine solution. Water vapors in the stream exiting the top of the still is condensed in the Reflux Condenser and collects in the Reflux Accumulator. The water is returned to the top of the tower using the Reflux Pumps, where it is commingled with the still liquid feed. The acid gases are vented from the Reflux Accumulator to disposal via the pressure control valve.

Amine collected in the after-weir section of the Reboiler is considered to be regenerated and is called “lean amine.” The lean amine is gravity fed through the Amine Exchanger to exchange sensible heat with rich amine and then go to the Amine Booster Pumps. The Booster pump boosts the lean amine pressure enough to pass through the Lean Amine Cooler where it is further cooled and delivered to the Amine Circulation Pumps. The Amine Circulation Pumps increase the amine pressure for it to enter into the top of the Amine Contactor and start the treating process over again.

5 Comments

Nitrogen Rejection Process for Natural Gas - Chemiopedia · September 19, 2022 at 5:17 pm

[…] Read Also: Amine Sweetening Process […]

Geldart Classification of the Fluidized Particles - Chemiopedia · September 19, 2022 at 10:43 pm

[…] You may like to read: Natural gas sweetening […]

Steam Methane Reforming Process - Chemiopedia · October 3, 2022 at 4:27 pm

[…] Read also: Amine Sweetening Process […]

Claus Process with Tail Gas Treating for Sulfur Recovery · December 1, 2022 at 3:18 pm

[…] Read also: Amine Sweetening Process […]

Natural Gas Sweetening (Physical and Chemical) Processes · December 3, 2022 at 7:37 pm

[…] Read More: Amine Sweetening Process […]

Comments are closed.